10 Mar, 2023

Non-Newtonian Fluids in Pipe Networks: Properties and Characteristics

The complex behavior of non-Newtonian fluids necessitates the need for more specialized studies when designing or optimizing fluid networks. Unlike their Newtonian fluid counterparts such as water, fuel oil, or vinegar, the resulting shear rate of a non-Newtonian fluid as it flows and undergoes shearing causes viscosity to vary and significantly affects the design and operation of its pipe network.

When mechanical energy is introduced to this type of fluid, a resulting shear stress would induce any or a combination of the following fluid behaviors:

- Fluid flows with a reduced viscosity

- Fluid flows with an increased viscosity

- Fluid does not move because the exerted shear stress is not enough to cause flow

Image 1: When enough shear stress is applied to a fluid at rest, the fluid will move according to its viscosity and the resulting friction between fluid “layers”. The rate of fluid deformation as shearing is applied is called shear rate.

To further understand non-Newtonian fluids, they can be categorized based on their ability to flow when a certain amount of shear stress is applied: yield and zero yield stress non-Newtonian fluids.

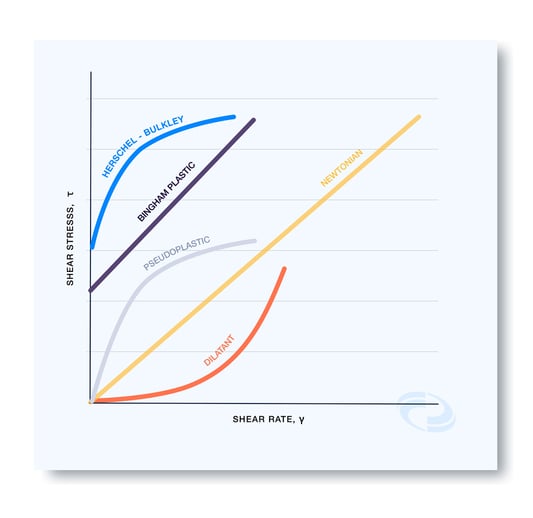

When a plot of shear stress versus shear rate is developed for a yield stress type, the curve does not start on the origin but rather at a specific point in the Y-axis.

On the other hand, zero yield stress types are plotted on curves that start at the origin.

Combining shear stress influence on the fluid viscosity, non-Newtonian fluids are further classified as:

Pseudoplastic Fluid

This type of behavior is observed in liquids such as paint, blood, or nail polish. When subjected to increased shear stress, its viscosity is reduced and is thus termed as “shear thinning liquid”.

Image 2: Paints demonstrate pseudoplastic behavior, it spreads evenly from the brush bristles to the wall when shear stress is applied.

Yield Pseudoplastic Fluid

This fluid behaves almost similarly to a pseudoplastic liquid except for one difference: it needs enough yield stress before it can demonstrate the ability to flow. This behavior is most notably observed in liquids such as ketchup, orange juice concentrate, whipped cream, and banana puree.

Image 3: Ketchup only flows when the bottle is squeezed to cause enough shear. Its viscosity is reduced as it is spread across a surface.

Dilatant

This fluid does not require yield stress in order to flow. However, when subjected to increased shear stress, its viscosity increases and is thus termed as “shear thickening liquid”. Several types of honey, custard, and cornstarch-water mixture display this type of behavior.

Image 4: Starch in water also called “oobleck”, as more shear stress is introduced through punching, more resistance to deformity is observed

Herschel - Bulkley

This behavior is encountered in fluids such as minced fish paste or raisin paste but is more commonly characterized by drilling fluids. Thus, it can be used to describe the behavior of non-settling slurries.

Image 5: Herschel Bulkley's type of behavior is often used to model non-settling slurries such as the flowing mud shown.

Bingham Plastic

This type of behavior is commonly observed in foodstuffs containing high fat; clay suspensions, toothpaste, tomato paste, and mustard. Like Herschel - Bulkley fluids, they require yield stress in order to flow. However, unlike the latter, it demonstrates a linear shear stress versus shear rate relationship. Hence, once the yield stress is exceeded, it would display its “plastic viscosity”.

Image 6: Viscosities of Bingham plastics tend to behave more as a Newtonian fluid as its yield stress gets closer to zero.

To summarize, shear stress greatly impacts the complex behavior of non-Newtonian liquids. Contrary to Newtonian behavior, its viscosity is dependent on shearing such that in some instances, it requires a certain stress (yield stress) in order for it to start flowing. On some fluids, adding more shear reduces the viscosity (shear thinning) while other types exhibit the opposite; its viscosity increases (shear thickening) when shear is increased.

Image 7: Different types of non-Newtonian fluids, curves starting from the origin are categorized as zero yield stress fluids while plots starting at a certain portion on the y-axis are called Yield stress fluids.

While this fluid behavior can be complicated, this characteristic can be captured in FluidFlow hydraulic models. Through the use of fluid information in the default database or by adding new rheology data, the impact of non-Newtonian behavior on pipe size and hydraulic performance of equipment such as control valves and boosters can be assessed by FluidFlow.

Got questions or new to FluidFlow? Send us a message at success@fluidflowinfo.com