Sulphur fuel limits....."A Sea Change”.

It has been quoted that the shipping industry is responsible for emitting around a billion tonnes of carbon dioxide (CO2) per annum. Efforts are being made by the IMO (International Maritime Organisation) to clean up the industry by introducing new limits for sulphur in fuel oil used on board ships. The current sulphur limit in fuel oil used on board ships for main and auxiliary engines and boilers for ships currently operating outside the Emission Control Areas is 3.5 % mass by mass up until 31 December 2019. The new limit set by the IMO will be in place from 1st January 2020 and will be 0.5 % mass by mass. This applies to ships operating outside designated Emission Control Areas. There are some exemptions that can be reviewed in literature published by the IMO. This change in limits will result in significant reductions in the amount of oxide emanating from ships. In summary, ships will be required to reduce sulphur emissions by more than 80 % by 2020.

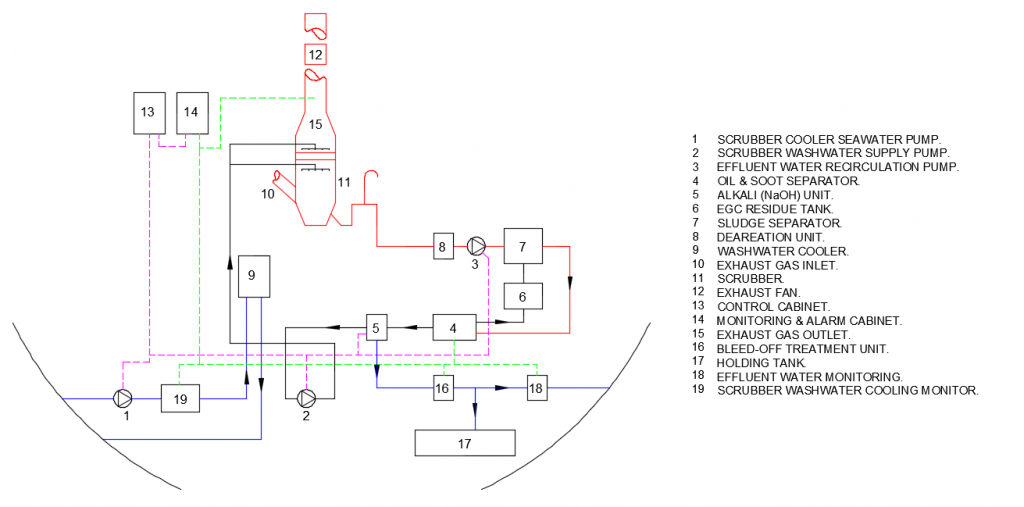

Ships can meet the new limits in a number of ways. Low-sulphur compliant fuel oil can be used and are already common in Emission Control Areas. Alternatively, ships can continue to use heavy bunker fuel if scrubbers are installed to capture harmful pollutants from exhaust gas. The latter option would require an upfront investment however, shippers would perhaps have a competitive advantage of being able to use lower cost higher sulphur content fuel. An article published by Hellenic Shipping Hews Worldwide indicates that scrubbers have become a feasible and popular option. In general, there are three different scrubber options available; open loop, closed loop and hybrid systems. Each option has its benefits and drawbacks. In open loop scrubber systems, seawater is used as scrubbing water. Water is taken from the sea, passed through the scrubber and returned to the sea. In closed loop systems, the system is filled with water which is recirculated. The water is therefore supplied from the sea. Only a small amount of water is released to the sea in a closed loop scrubber system. Finally the hybrid option is as you would guess a mix of the open and closed loop systems. This system can operate in both open and closed loop modes. Figure 1 gives an overview of a closed loop system.

Ships with scrubbers are considered to be in the minority and as of May 2018, just 494 vessels were noted as having scrubbers installed. This of course is out of circa. 90,000 commercial vessels on the World’s seas.

Taking a more longer-term approach on the subject, it is considered that LNG (liquefied natural gas) is expected to become a more prominent part of the shipping sector’s fuel supply since it produces almost no SOx or particle matter emissions. Indeed, two recent examples of vessels using LNG are Containerships Polar, a commercial cargo ship and the AIDAnova cruise ship which is the world’s first cruise ship to be driven by LNG. FluidFlow software was used successfully for modelling the piping systems onboard both vessels. The software is used widely in shipbuilding to model fire-fighting, fuel oil, exhaust, effluent, sea water ballast, air flow, open and closed loop cooling systems to name a few.

References:

- International Maritime Organisation.

- Hellenic Shipping Hews Worldwide.