The importance of accurate slurry rheology and slurry viscosity data

The characteristics of slurry viscosity are defined by its rheology which describes the deformation and flow behaviour of materials, both fluids and solids. It applies to fluids which exhibit complex microstructures such as sludge and suspensions, mud, fluid-foods etc. These fluid types are regularly encountered in mining and mineral processing industries as well as food processing and pharmaceutical processes. In order to design and develop accurate and efficient piping systems, a good understanding of the rheology of slurries and slurry viscosity is essential, and determination of the slurry rheology is of paramount importance.

Slurry rheology is affected by various attributes such as mass fraction, shape, size, density etc of the solid particles suspended in the slurry as well as the density and viscosity of the carrier fluid, typically water.

It probably comes as no surprise that one of the most important rheological attributes to be considered is the slurry viscosity. The viscosity of a Newtonian fluid, unlike a non-Newtonian fluid, is independent of shear rate. The more common rheology models used to characterise non-Newtonian fluids include the Herschel-Bulkley, Power Law, Casson and Bingham Plastic models, all of which are available in FluidFlow software.

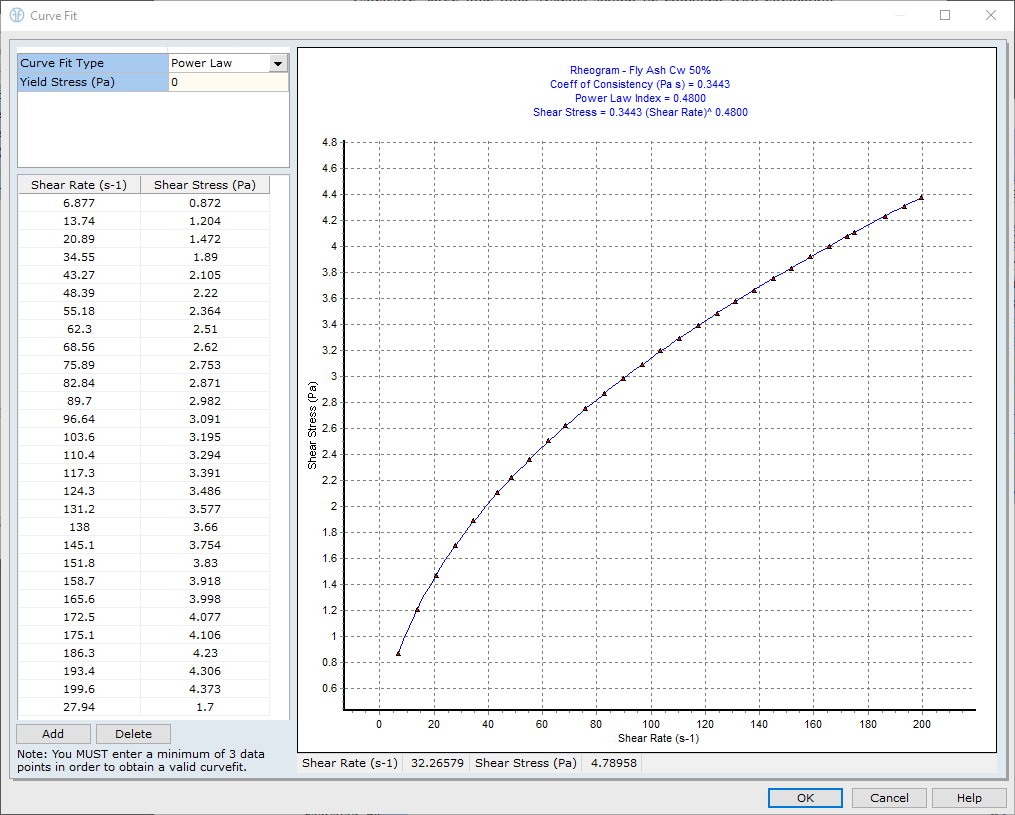

FluidFlow allows you to plot the curve relationship of shear rate vs shear stress or define the slurry viscosity equation constants. The method you choose is largely dependent on the available slurry rheology data. Figure 1 gives an overview of fly ash defined as a non-Newtonian fluid. In this instance, the Power Law viscosity relationship has been applied effectively to the slurry shear rate and shear stress characteristics.

Figure 1: Fly Ash Shear Rate vs Shear Stress – Power Law Fluid.

The slurry density is also an important characteristic. The density of a slurry is affected by the density of the carrier fluid as well as the density of solid particles and concentration of solid particles in the slurry. Although the concentration of solid particles is regularly defined by weight percent (Cw), the concentration can be defined as either weight or volume percent in FluidFlow.

Sample on how to add a non-Newtonian Fluid to the Database in FluidFlow

When designing or modelling a slurry flow system, sourcing good slurry rheology data is vital. Having good data combined with a good software tool will help enormously with the sizing and selection of piping, pumps valves and fittings. It will also help greatly with the economic considerations of the project. Insufficient or poor rheology data on the other hand can be a contributing factor in the failure or success of a project. FluidFlow software helps you characterise your slurry based on the rheology and slurry viscosity data you have available. This saves time and helps validate the slurry data giving confidence in the developed system design/model.

If reliable on-site data, literature data or prior experience is unavailable, the first step is to complete laboratory testing to determine the rheology of the slurry.

Once reliable data has been sourced, the next step of course is to design the slurry system. Here are some general and useful tips to help with this challenge:

- Minimise pipe length to minimise pressure losses.

- Ensure pipes are as straight as possible to minimise pressure losses and wear.

- Install pipes in a sloped manner to facilitate emptying of pipes.

- Pipelines with low velocities should be eliminated in an effort to avoid settling of particles and prevent sanding and ultimately, pipe blockage.

- Minimise number of pipe fittings.

- Install drain valves and flushing inlets.

- Pockets and blind areas should be avoided. Where this is not possible, provide a drain valve.

- Install wider bends to reduce pressure losses and wear.

This blog discussion has been kept brief in an attempt to target some key points (slurry viscosity and slurry density) in slurry flow design. Designing slurry piping systems can often be a complex challenge, however, the above should help with some of the basics.

Related Content:

Slurry Piping Systems in Mining & Mineral Processing Industries - FluidFlow