27 Mar, 2023

Maximizing Efficiency with Control Valve Sizing and Cv Value Calculation: A Guide for Industrial Applications

Control valves are essential in ensuring fluid systems to run within its desired operating range. While meeting the required flow condition is the main objective of control valve sizing, identifying the most appropriate size is also dependent on other factors. An oversized or undersized control valve will lead to unnecessary pressure drop that results in a less efficient operation. It can also cause poor process control, plant upset, and potential damage to the equipment.

Figure 1: Typical control valve assembly in a processing plant. The structure on top of the control valve is called an actuator and positioner.

Control valve size is characterized mainly by its Cv value. This parameter is a representation of a control valve's capacity to accommodate a certain flow rate of water at 60°F in gallons per minute (gpm) as it generates a pressure drop of 1 psi when flow passes across the valve.

In this article, we will explore how Cv values are calculated and its importance in ensuring a more energy-efficient fluid system.

Understanding Control Valve Sizing:

Control valve sizing is the process of determining the appropriate valve Cv that will be able to regulate fluid flow at a desired amount and condition. The value of a control valve Cv is dependent on the following factors:

- Fluid flow rates at their various scenarios such as the required Maximum, Normal and Minimum flow

- Fluid composition in order to generate the fluid properties such as density, viscosity, vapor pressure, specific heat capacity, and thermal conductivity

- Control valve inlet and outlet line sizes

- Source or destination pressure to determine fluid conditions at the Control valve nozzle

- Available pressure drop for the control valve

Figure 2: A control valve assembly with reducers at the inlet and outlet of the valve.

Calculating Cv Value:

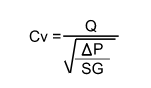

The first step in finding the optimum size of a control valve is to determine the Cv value, defined as the volumetric flow of 60°F water in gallons per minute that can pass through the valve at a pressure drop of one (1) psi. The fastest way to calculate the Cv value is by using the following formula (Equation 1):

Equation 1

Where:

Q = flow rate in gallons per minute (gpm)

ΔP = pressure drop across the valve (psi)

SG = specific gravity of the fluid

By inputting the values of the flow rate, pressure drop, and specific gravity into Equation 1, we can calculate the Cv value for a particular control valve. Full explanation for Cv and detailed control valve sizing can be found here: Control Valve Sizing - FluidFlow.

Installing a control valve with an improperly sized Cv may result in undesirable results in any of the following ways:

When the control valve is undersized due to low Cv value for a specific application:

- The valve will not deliver the required amount of fluid in the process thus resulting in process starvation or bottlenecks.

- Valve restrictions can increase the upstream delivery pressure which may result in the failure of upstream equipment.

- Higher pressure will be generated which is prone to cavitation and/or flashing.

On the other hand, if the Cv value is high for the application:

- This will result in oversized control valves which may result in an increase in cost, space requirement, and weight loading of the control valve.

- The control valve will result in significant control problems if used in throttling service. Additionally, higher pressure drops and faster velocities lead to cavitation, flashing of process fluid, and/or erosion of valve parts.

Optimized Control Valve Sizing:

To ensure control valve size is optimized, follow these guidelines:

- Establish the flow required from the control valve with minimal flow margins for uncertainty to prevent oversizing

- Accurately determine the physical property of the fluid to be handled by the control valve

- Determine an accurate pressure loss profile of the system through detailed pressure loss calculations on components connected to the control valve such as pipes, bends, fittings, and other “between piping” elements that can cause pressure drop

Figure 3: FluidFlow has the feature to autosize control valves and give recommendations based on control valve models offered by Manufacturers.

While the first item above will depend on one’s engineering judgment, FluidFlow will be able to help with the other items in this guideline. This will ensure control valves installed on piping systems demonstrate optimum performance.

Conclusion:

Calculating Cv values is a critical aspect of control valve sizing and ensuring optimal fluid flow control. Selecting the optimal control valve size will result in increased efficiency and reduced energy consumption. It is important to note the factors that affect Cv value such as application, fluid properties, required flow rate (all process cases considered), and available pressure drop for the control valve. Following the guidelines will ensure that control valves will efficiently control the flow while minimizing pressure drop, resulting in optimal process control and equipment performance.

FAQs:

What is the difference between Cv and Kv values?

Cv and Kv values are both used to describe the flow rate of fluid through a valve. The primary difference is the unit of measurement. Cv values are expressed in gallons per minute (gpm), while Kv values are expressed in cubic meters per hour (m3/h).

Can Cv values be calculated for gases?

Yes, Cv values can be calculated for gases using the same formula used for liquids. However, the specific gravity of the gas must be substituted for the specific gravity of the liquid in the formula.

What is the relationship between Cv value and pressure drop?

The Cv value is inversely proportional to pressure drop. As pressure drop increases, Cv value decreases.

Can control valves be oversized?

Yes, control valves can be oversized. Oversized valves may lead to poor process control, fluctuating pressure, and potential damage to the equipment. Therefore, it's essential to accurately calculate the required Cv value and select the appropriate control valve.

What is the impact of incorrect Cv values on energy consumption?

Incorrect Cv values can lead to excessive pressure drop, resulting in increased energy consumption and reduced efficiency. Therefore, selecting the correct Cv value is critical in minimizing energy consumption and optimizing efficiency.

References:

How to Size a Control Valve and Why it’s Important, Crane Engineering

Size Matters: Control Valve Sizing 101 by Jon Monsen, Ph.D., Valve Magazine

What is CV, and How Do I Calculate It? by Aaron Nobel, Belimo Holdings AG