Common Pitfalls of Large-Diameter Hydraulic Piping System Design

Piping System Design; Much has been written about common problems with poorly designed pumped piping systems. Whilst there is no “one size fits all” or “rule of thumb” solution for all systems types, i.e. liquid, gas, slurry, two-phase etc, the following should serve as a useful baseline consideration for water transmission pipelines.

It can be common practice for engineers to use template design calculation sheets for liquid transmission lines which utilize rules-of-thumb as part of the template for design. This can often result in the failure to acknowledge inherent differences from one project to the next. In large-scale water supply projects, errors in hydraulic system design such as underestimating friction losses can be magnified resulting in reduced system capacity, catastrophic failures or even the potential for litigation.

Mistake #1: Underestimating Pipe Friction Losses

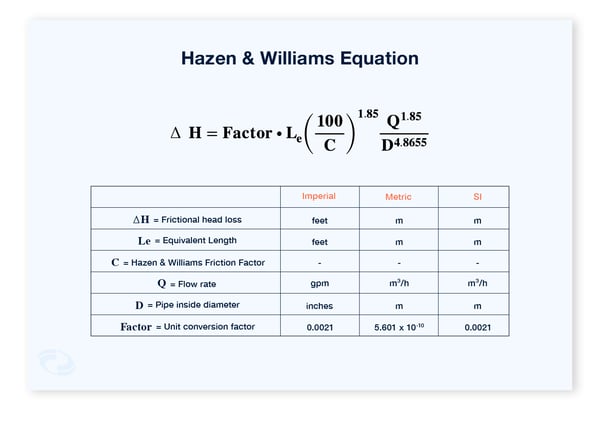

A common mistake in the design of large-diameter pipelines is underestimating pipe friction losses. A widely used method for determining friction losses is the Hazen-Williams (H-W) equation as it is relatively simple and easy to use. This equation is empirical and in the design of

The Hazen-Williams equation relates the flow of water in a pipe with the physical properties of the pipe and the pressure drop due to friction. The equation uses a pipe roughness coefficient, “

The Hazen-Williams equation has been used for over a century and, despite its range limitations there is a large database of available information about the inner surface roughness of pipes as they age.’ Evidence suggests that many hydraulic engineers use the Hazen-Williams formula outside its valid range but researchers have “introduced C-value as functions of pipe diameter and equivalent sand-grain roughness” to make the formula produce reasonable results. A word of caution however for design engineers. It is good design practice to consider a range of Hazen-Williams C-factors when calculating friction losses over the life expectancy of a given pipeline.

The Hazen-Williams equation has been used for over a century and, despite its range limitations there is a large database of available information about the inner surface roughness of pipes as they age.’ Evidence suggests that many hydraulic engineers use the Hazen-Williams formula outside its valid range but researchers have “introduced C-value as functions of pipe diameter and equivalent sand-grain roughness” to make the formula produce reasonable results. A word of caution however for design engineers. It is good design practice to consider a range of Hazen-Williams C-factors when calculating friction losses over the life expectancy of a given pipeline.

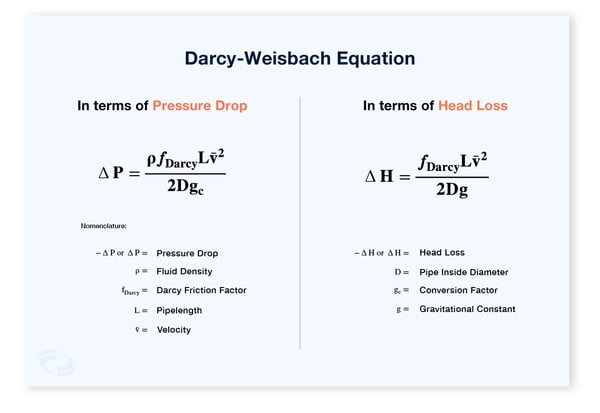

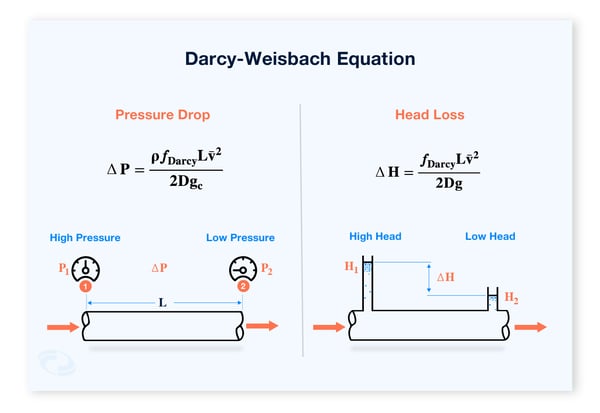

The Darcy-Weisbach equation provides a much better approximation of friction loss by comparison with the Hazen-Williams equation as it considers Reynolds number and pipe roughness for different pipe materials and is valid across all pipe sizes and turbulent flow ranges. The equation is dimensionally homogeneous, can be used for any pipe sizes with fluid at any temperature under any flow range and with any liquid/incompressible fluid.

Mistake #2: Overestimating Pipe Friction Losses

It is prudent when designing piping systems to accurately and conservatively estimate pipeline friction losses however, the engineer needs to also be wary of being too conservative and overestimating friction loss. If the actual operating friction loss is less than estimated at design, the resultant discharge flows will be higher than anticipated. Overestimating friction loss can lead to less efficient operation of pumps which operate in less efficient ranges of the pump performance curves, and installation of larger pumps, motors, pipe, and equipment than what is actually needed for the required flow rates. It is also documented in published literature that a fear of insufficient capacity for future flow rates often leads to the most frequent and worst blunder of all……choosing pumps and pipes too large for the actual flows to be encountered. This can ultimately lead to premature pump failure, poor operating conditions, wasteful energy usage, higher operating costs and higher capital installation costs.

Poor design on multi-million dollar water transmission systems can be disastrous to system operators and owners and cost million of dollars extra due to reduced water supply, increased water rates and required public expenditure on additional water supply sources. It is essential that a designer is aware of the inherent differences between each project and avoid applying a rule of thumb approach or one fits all spreadsheet to calculate the system conditions.

References:

1. ASCE Pipelines 2011.

Related Articles:

Pump Sizing - The Effects of Oversizing Centrifugal Pumps